From the Stone Age to modern times, humans have mined the earth for valuable stone and mineral materials used in a variety of applications. From the Stone Age to recent times, humans have mined the ground for precious stone and mineral resources to be used in a variety of applications. From fashioning crude tools to fashioning exquisite jewelry, humans have dug and tunneled into the earth to access those precious materials. The history of mining is a long one, and its importance continues today.

Unfortunately, mining has always been a dangerous endeavor, and countless miners have given their lives to the industry. Today, mining remains a hazardous career, but modern advances have improved conditions for workers. Among these advances are the safety and health standards enforced by the MSHA, mandatory safety training, and innovative personal protective equipment (PPE).

At MCR Safety, we design PPE that protects miners from numerous mining-related hazards. On our Mining Industry page, we highlight the three core sub-industries and the PPE often used across each.

Â

MCR Safety's Mining Industry Resource Page

In this article, we will discuss the MSHA, safety training, PPE, such as breathable FR clothing, and much more.Â

What does MSHA stand for, and what is MSHA?

MSHA stands for the Mine Safety and Health Administration. So, what does the administration do? MSHA works to prevent death, illness, and injury across mining operations in the U.S. They accomplish this by promoting safe and healthy workplaces, developing safety-related rules, and then enforcing those rules. Mining has always been a dangerous industry but viewed as an essential operation.Â

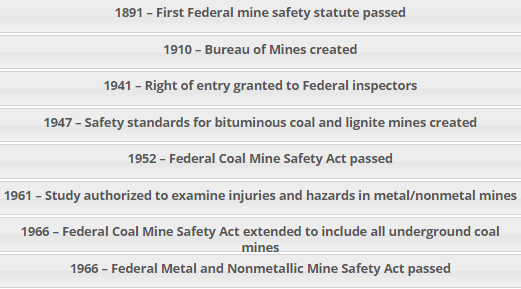

After recognizing the enormous risks to miners’ health, the U.S. federal government began passing legislation to protect miners back in the late 19th century. In 1891, the government passed its first mine safety statute, which established minimum ventilation requirements in underground coal mines and prohibited the employment of children under the age of 12. Since then, small but incremental changes have continued to be made to improve working conditions for miners.Â

A visual timeline of the U.S. legislation passed to enhance mine safety.

The Federal Coal Mine Health and Safety Act of 1969 is recognized as the most comprehensive legislation up to that point concerning mining safety. This act was later amended in the Federal Mine Safety and Health Act of 1977 (Mine Act), which drastically cut mining fatalities and established the U.S. Department of Labor’s Mining Safety and Health Administration (MSHA) to oversee the industry.Â

Since its inception, MSHA has enforced compliance with the safety and health standards established by the Mine Act. The agency’s mission is to prevent death, illness, and injury from mining and to promote safe working conditions for miners. It does this by developing and enforcing safety and health rules for all U.S. mines, including mandatory safety training.

What is MSHA training?

One of the ways MSHA promotes mine safety is through mandatory training. Federal law requires that all miners obtain annual safety training to prevent injuries and fatalities. To assist miners, MSHA provides a wide array of materials to ensure all miners receive this training. Here are several helpful MSHA websites.

- Safety Database – manuals, presentations, and guides listing potential hazards

- Safety Videos – training videos on health and safetyÂ

- Safety Alerts – information for equipment hazard alerts

For additional resources, check out the MSHA websites listed below.Â

https://www.msha.gov/training-education

https://www.msha.gov/training-education/safety-health-materials

MSHA Certification: MSHA Part 46, MSHA Part 48, and MSHA 5000-23

MSHA provides hundreds of resources to help miners become trained in identifying the potential mining hazards they may face. However, these resources come with the expectation that all new miners must become safety-certified. They are required to complete a minimum of 24 hours of training within their first 90 days of employment. Before a miner is even allowed to work in the mine, they must complete at least four hours of safety training, and there are two core certifications miners must complete. Here are the two, with differences shown for each and links to MSHA’s reference guides:

MSHA Part 46

This training pertains to the training and documentation requirements at mines. It applies to miners who work in shell dredging, gravel, limestone, sand, colloidal phosphate, and clay mines. Essentially, this means that it applies to all non-metal, non-coal mines. This training mandates that all miners must receive health and safety training, the mine’s training plan must be available to miners and MSHA at all times, and a designated person must keep all required training documentation. Part 46 training plans do not have to be approved by MSHA before implementation.

MSHA 46 Reference Guide

MSHA Part 48Â and Form 5000-23

This training plan applies to all underground mines not covered by Part 46. When miners have completed MSHA 48 training, they receive a copy of Form 5000-23. This certificate of training is kept as proof to the MSHA that the training was completed.

Keep in mind, MSHA has specialists available to assist mines in complying with this training regulation. These specialists work for a division called Educational Field and Small Mine Services (EFSMS). They travel to mines and provide the mining community with industry-specific health and safety programs.

MSHA 48 Reference Guide

Mine Accidents, Injuries, and Illnesses

MSHA collects data on all aspects of mining, including accidents, injuries, and fatalities. These incidents are reported by the mines and published on the MSHA website for reference. When an accident occurs at a mine, management must complete Form 7000-1 and mail it to MSHA within ten working days after an incident takes place. Click the image below to access the form.

Â

Form 7000-1

Â

Due to the work environment, tools, and tasks of mining, miners face many health and safety hazards. While laws and safety training help reduce many of these risks, nothing can remove them entirely. Here are some of the most common afflictions and accidents caused by mining:

- Burns from fire and explosions

- Cuts and bruises from working with tools and hard materials

- Chemical burns, poisoning, and respiratory issues

- Hearing loss from the constant noise of drilling and heavy machineryÂ

- HeatstrokeÂ

- Lung disease from dust inhalation

- Musculoskeletal disorders from machine vibration, heavy lifting, and repetitive motions

- Sunburn and skin cancer from UV-ray exposure in open-pit mines

Luckily, the risk of all of these conditions and accidents can be reduced when miners follow MSHA recommendations for personal protection equipment.

MSHA’s PPE Recommendations

Due to the number of health and safety risks miners face, many MSHA standards require miners to wear personal protective equipment (PPE). Compliance with these standards is subject to inspection. Some of these standards include:

- 30 CFR §§ 56/57.15004 Eye protection;

- 30 CFR §§ 56/57.15014 Eye protection when operating grinding wheels; and

- 30 CFR §§ 56/57.15007 Protective equipment or clothing for welding, cutting, or working with molten metal.Â

Personal protective equipment (PPE) includes everything worn by a miner to prevent injury or illness. A few examples of mining PPE highlighted by MSHA that MCR Safety offers include:Â

- Safety glasses – MSHA says safety glasses should be worn across all areas of a mine.

- Face shields and goggles – This PPE should be worn when operating a grinder.

- Gloves and Sleeves – Both protection and finger dexterity must be considered when selecting an appropriate glove for mining. MSHA states that wearing different types of gloves in various applications may be necessary to protect against multiple hazards. PPE, such as gloves and sleeves, are excellent at protecting workers from hazards. However, when working around rotating equipment, avoiding the risk of PPE becoming entangled is essential. In such situations, a Utility Clip should be used to safely secure gloves or sleeves away from the body, preventing them from getting caught in machinery. This clip is specifically designed to keep PPE out of the way while equipment is in operation.

Â

Miners should consider keeping their PPE on their Utility Clip when working around rotating equipment.

Â

- Chemical-resistant clothing – Chemicals used in mining operations can be caustic. Check out our chemical permeation database for an in-depth look at permeation breakthrough times.

- Heat-resistant clothing – Wearing clothing designed to protect against contact with hot materials will help keep miners safe.Â

It is up to each mine to follow MSHA guidelines and provide PPE for employees. To ensure the appropriate PPE for miners, employers should analyze the hazards workers face and select PPE that reduces those hazards. For example, a miner who works with chemical lines should receive long gloves, aprons, footwear, and a face shield that protects them from chemicals without inhibiting hand dexterity or sight. Each mining operation must perform extensive safety hazard assessments before allowing work to begin. Otherwise, the costs can be high for both the mine and the miner.

Additional Resources

MSHA PPE

MSHA's PPE guide should be the official source for determining mining PPE,

PPE and Protection from Electric Arc

Electric arc injuries are one of the most common types of electrical injuries in mining. When an electric current passes through the air, between ungrounded and grounded conductors, it creates an electric arc flash. Temperatures may reach as much as 35,000℉ and cause severe burns.

Here are five types of apparatus that may cause this injury in mining:

- Circuit breakersConductors

- Non-powered hand tools

- Electrical meters

- Connectors and plugs

A study by the National Institute for Occupational Safety and Health (NIOSH) from 1990-2001 found there to be a total of 836 electrical accidents in mines during that period. The number may appear low for a decade long study. However, when you take into consideration that an employee's medical expenses after an arc injury can cost millions of dollars, it’s a big deal. A couple of interesting facts came out of this study. First, 55% of all these injuries occurred in bituminous coal operations. Second, troubleshooting and repair activities caused 42% of all injuries. As we mentioned above, MSHA’s collection of injury reports provides data to assist mines and safety managers in preventing future injuries.

Miners who are at risk for electrical arc injuries should wear fire-resistant PPE. While not fireproof, FR clothing dramatically reduces the risk of injury from electric arc flashes and other heat sources. FR clothing provides the following benefits to miners:Â

- Does not ignite, melt, drip, or continue burning

- Increases one’s probability of surviving the hazards mentioned above

- Insulates the wearer from heat

- Maintains a barrier from flames

- Resists being broken apart

- Provides workers with escape time

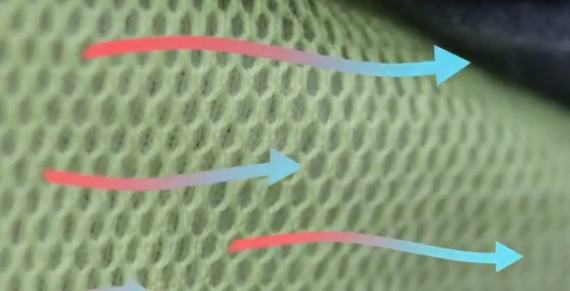

We recently introduced a new lineup of FR clothing made with triple vents, providing miners with an excellent breathable feature for hot mines. We discuss this new technology in the next section.

FR Clothing and Summit Breeze®

In addition to burns, heat stress is another common hazard miners face. The MSHA recognizes the need for miners to stay hydrated and cool. To prevent heat stress, MSHA recommends wearing loose-fitting clothing made of light cotton that allows sweat to evaporate and transfer heat. Our new FR clothing with Summit Breeze® technology is designed to help. Â

What’s unique about this technology? Its mesh triple-venting is incorporated onto the back and under the arms, allowing body heat to escape where it builds up the most.

Summit Breeze® Technology

Â

Summit Breeze® technology provides better heat stress management for those working in a hot environment, those who are performing labor-intensive tasks, or a combination of the two. When working in an environment prone to heat stress, vented openings can be a lifesaver. MCR Safety is the only manufacturer providing FR clothing with three total FR mesh vent openings, allowing for exceptional airflow. Â

Â

Promoting Mining Safety with PPE

It is impossible to cover all the mining safety guidelines established by MSHA. For more information not included here, this link serves as a useful resource.  MSHA oversees mining conditions, set training standards, mandates PPE requirements and enforces safety, ensuring the well-being of miners throughout the U.S. Mining will always be a dangerous industry. Still, by participating in mandatory safety training and wearing quality PPE, miners can avoid most injuries and death. Â

Click the image above to request a quote, leave us a comment, ask a question, or share any concerns.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's on the shop floor, an oil rig, or a construction site, we are there to provide solutions to workplace hazards. It's all part of our commitment to protect people.Â

No matter your industry, we have the personal protective equipment you need.

Â

Â

Â

Â

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at (800) 955-6887.

Magnetic Crane,Mobile Overhead Crane,Overhead Crane Magnet,Magnet Crane Machine

VOITH CRANE , https://www.voithcraneasia.com